You are Watching

The Wine Press

There are numerous remnants and varieties of winepresses to be found throughout the Valley, the result of a gradual technical evolution applied by the people of El Hierro over time in order to improve the efficiency of the places where grapes were treaded. This technical evolution is evident both in the nature of the materials used in the winepress and in the types of press employed.

The earliest wine presses were carved directly into the rock, quite primitive and only briefly used before an increase in production led to the crafting of wooden vessels for grape crushing. These wooden wine presses stood the test of time until they were replaced by those made of stone and concrete, which offered superior functionality.

Regarding the type of press, today, as we roam our fields, we encounter ancient dolly presses, with the widespread spindle presses, a legacy of a glorious past, and with the latest modern additions, the power presses or hydraulic presses. In the dolly press, the must was obtained from the pressure exerted by an articulated beam upon the foot-trodden grapes. This pressure was achieved by loading stones onto the free end of the beam.

In the screw press winery, the must is also extracted by the pressure of a hinged beam. However, as these wineries are intended for large volumes, the pressure from the beam (larger and heavier) is achieved by hanging a substantial stone from the free end and suspending it above the ground through a screw mechanism.

In modern wineries with mechanical or hydraulic presses, the beam as a tool for exerting pressure is no longer used. Instead, pressure is achieved through ingenious systems of screw-based pressing, hydraulic jacks, and the like.

WORK IN THE WINERIES

- Emptying the grapes into the winepress..

- Treading the grapes.

- Draining the must (grape juice) from the treading floor to the settling vat.

- Detemming: Removing the stems or "rachis" from the skins or "pomace", to press again.

- Forming the 'pie': Involves preparing the trodden clusters to extract the remaining juice, by pressing in the winepress.

- 1.- Gather the crushed material towards the centre of the winepress.

- 2.- Construct the cake using the rope and its stake for assistance.

- 3.- Position the wooden elements (the judges, the boards, the pigs, and the pressure plates) to apply the correct pressure.

- 4.- Compress the cake with a beam or other pressing systems until no more liquid is released.

THE WORK

- Operations:

Once the pressing of the cake is complete, to enhance the extraction of the liquid, two main actions are carried out:

- Desengaño involves dismantling the foot by separating in the bunches, the "enganzos" or stems, from the "bagos" or skins, to remove the former from the winepress and to repress, by means of a new foot.

- Performing the cut: this involves detaching all the external part of the grape pomace, to reposition this marc at the centre of the same mass and then pressing it again. This operation is repeated as many times as deemed appropriate.

Once the pressing was complete, and the last drops of must had fallen into the trough, the must was collected and transported to the cellar in barrels or demijohns. The pomace, after being removed from the press, has traditionally had multiple uses, such as feed for livestock, fertilizer for vegetable gardens, fermentation for brandy, etc.

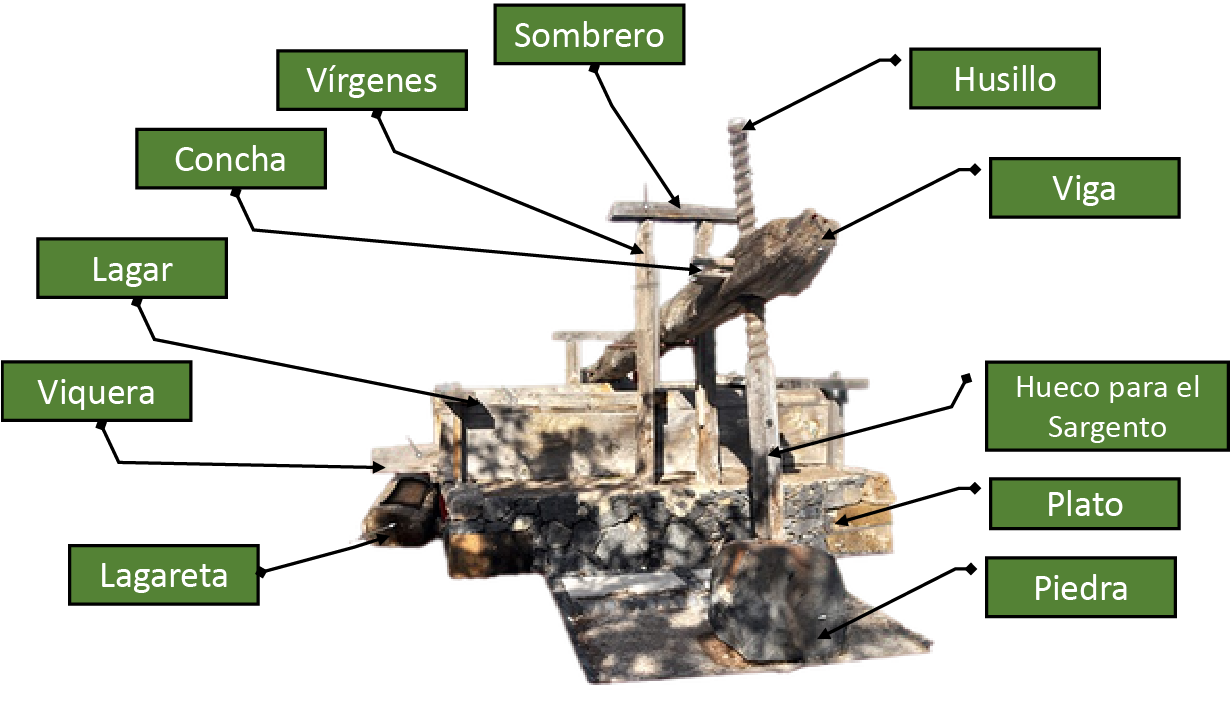

PARTS OF A SCREW PRESS

PARTS OF A SCREW PRESSO

- Winepress ("Lagar"): where the grapes are trodden.

- Must-gathering area ("Lagareta"): where the grape juice accumulates.

- Juice channel ("Viquera"): conduit through which the grape juice flows.

- Beam ("Viga"): wooden log used to apply pressure.

- Cheeks ("Virgenes"): two stakes between which the beam is raised and lowered.

- Screw spindle ("Husillo"): screw for raising and lowering the beam.

- Yoke ("Concha"): wooden piece that connects the beam with the screw spindle.

- Gudgeon of the stone ("Pernio"): piece of iron through which the screw spindle pulls.

- Stone ("Piedra"): large rock used to exert pressure.

- Key or keyholder ("Chaveta"): for locking the gudgeon to the screw spindle.

- Plate ("Plato"): piece that prevents friction between the screw spindle and the press stone.

- Sergeant("Sargento") : stick used to turn the screw spindle.

WINEPRESS.